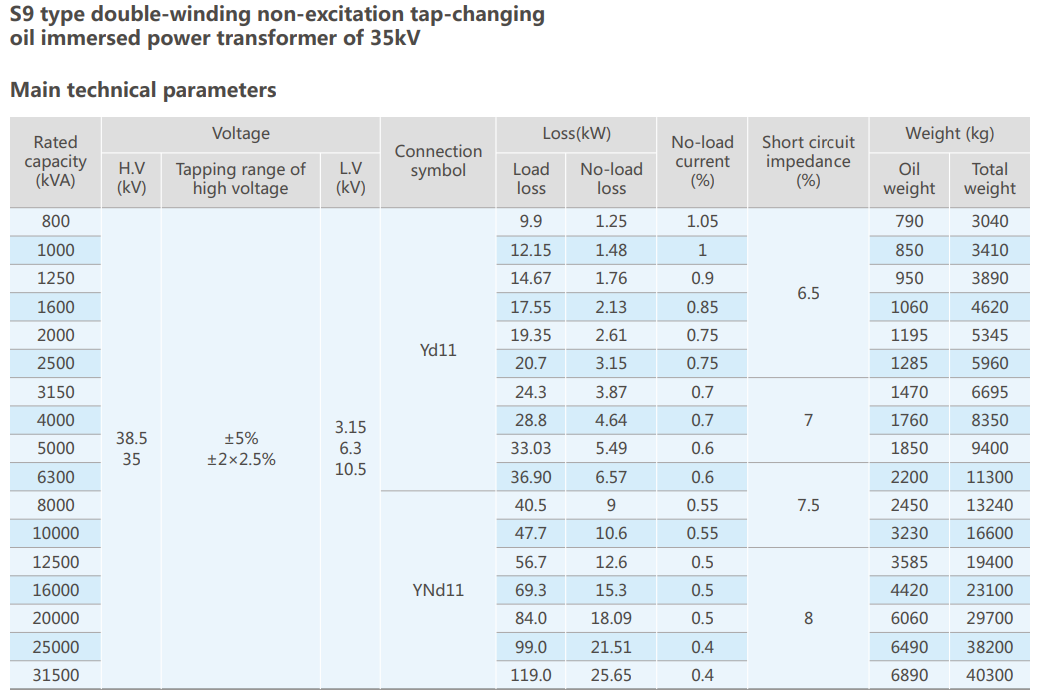

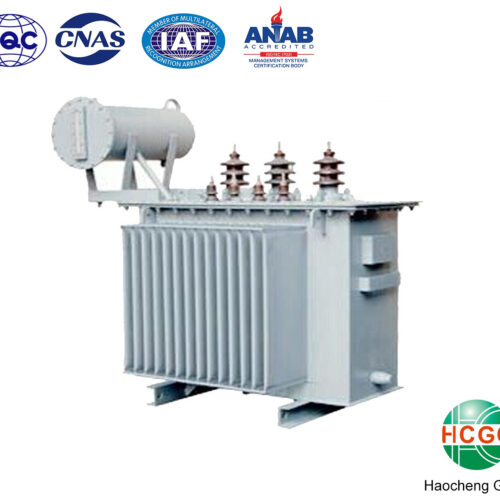

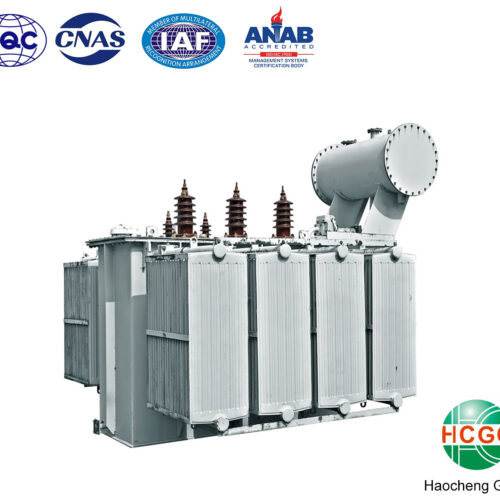

Tap-changing Transformer of 35kV and Below

This kind of product is applied to power system of three-phase, 50Hz as well as 35kV and below, it is the main transformer equipment of medium and small-sized transformer substation, supplies power distribution, power and illumination for the industry and agriculture.

The company introduces in domestic and overseas advanced technique, adopts the latest material and optimizes design, which enables the product structure more reasonable, and greatly improves the product electric strength, mechanical strength and heat-sinking capability. S9 series product has passed the short-circuit test prepared by Wuhan High Voltage Research Institute and also the test prepared by National Center for Quality Supervision & Test of Transformer.

Features

*Iron core

The iron core is made of high quality cold rolled silicon steel sheet, adopts the kinds of types like full-bias multi-step seam, no punched hole, winding iron core,etc., besides, both stainless steel stay plate and epoxy glass belt are for clamping it.

*Coil

High quality enameled wire that is made of oxygen free copper or paper wrapped flat copper wire is used as conductor, the coils is provided kinds of types such as drum type, spiral type, improved spiral type, continuous type and interleaved type.

*Oil tank

The oil tank is of barrel type or shield type, the heat-sinking element is provided with corrugated plate or plated radiator.The transformer has not been equipped with trolley, but there is a base that accords with national standard rail gauge welded at the bottom of box for your convenience.

*Safety protection device

According to national standard and users’ requirements, the transformer may be equipped with following safety protection devices: pressure relief valve, gas relay, signal thermometer, oil purifier, oil conservator, oil sampling valve, etc.

Implementation of the standards

GB1094.1-1996 GB1094.2-1996 GB1094.3-2003 GB1094.5-2003

GB/T6451-2008 GB311.1-1997 JB/T10088-2004

Service Environment

Altitude: ≤1000m

Ambient temperature: the highest temperature +40℃, the highest monthly mean

temperature +30℃; The highest yearly mean temperature +20℃.

Installation environment: inclination of installation place<3°, no obvious dirt and

corrosive or flammable gas.